Hi, I'm Aidan Robleto

I’m a mechanical engineering major at Cal Poly SLO who loves to make things. Here’s a portfolio of my best work – feel free to explore!

My Projects

Extracurricular Projects

Dulcimer Liquid Bi-Propellent Rocket Engine

I helped to design, manufacture, and test the injector for Cal Poly Space System’s first ever liquid bi-propellent rocket engine, named Dulcimer. Using ethanol as fuel and nitrous oxide as oxidizer, Dulcimer was designed to be fuel-rich with a mixture ratio of 1.5 (oxidizer to fuel), and fire with 25 pound-force of thrust.

Utilizing MATLAB and SolidWorks, I designed the injector manifolding that routes the propellants from the feed system into the combustion chamber. I then helped to manufacture the stainless steel injector plates using a lathe and mill.

I also worked closely with the combustion chamber and test stand teams to integrate the injector plates with the rest of the assembly.

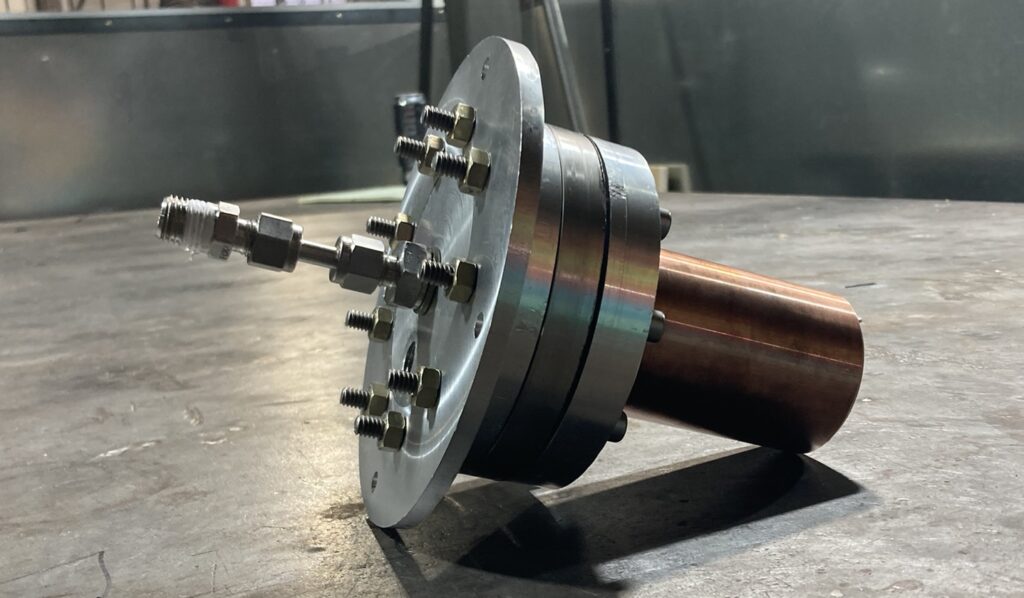

The injector plates and combustion chamber and nozzle, fully assembled for the first time.

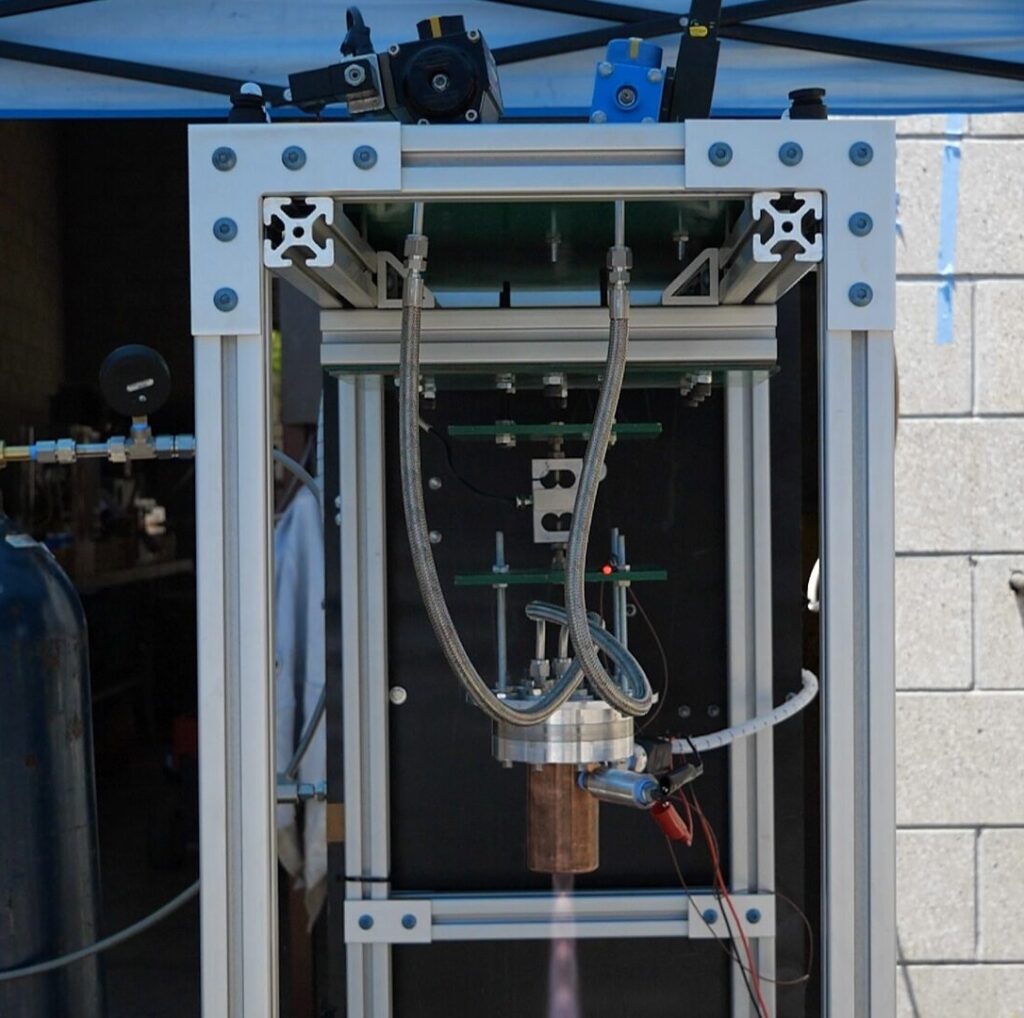

Flow testing with water to ensure proper impingement for the propellent streams. This, along with hydrostatic pressure testing, was conducted prior to cold-flowing real propellant through the engine.

Drilling the nozzle orifice holes on the bottom injector plate.

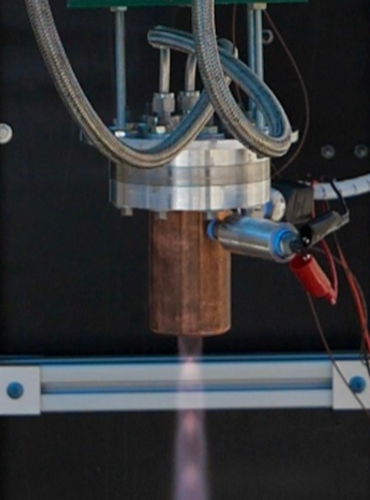

The first successful hot-fire test of Dulcimer in June 2023. Note the presence of “mach diamonds” in the exhaust plume, indicating supersonic flow.

Project Dulcimer 2023 Recap, Cal Poly Space Systems. A quick overview of the club’s manufacturing and testing process.

Cycloidal Drive

As the Hip Technical Lead for the Lower-Limb Exoskeleton Assist Project (LLEAP), I led a team of mechanical and biomedical engineers in making the hip joint for an exoskeleton suit. The hip joint featured a 104:1 gear reduction, which was accomplished using a 4:1 Maxon planetary gearbox and and a 26:1 cycloidal drive (designed and manufactured in-house).

I wrote a MATLAB script to determine the optimal values for the rotor radius, cam eccentricity, fixed pin radius, roller radius, and number of rotor lobes. The script output a set of parametric equations that could be plugged into SolidWorks’ equation-driven line tool. After designing the cycloidal drive assembly around these parameters, each part was either purchased or dimensioned, toleranced, and manufactured at Cal Poly’s Machine Shops.

Planetary Gearbox

This section is currently in progress – please check back in later!

Personal Projects

L1 Certification Rocket

I built Hyperion I with the goal of completing my Level 1 High Power Rocketry Certification through the Tripoli Rocketry Association. Designed and simulated using OpenRocket and SolidWorks, Hyperion I consisted of a cardboard body tube, laser-cut wooden fins and centering rings, and a 3D printed nosecone. Equipped with an on-board flight camera and an Aerotech H100W-14A motor with 52.6 pound-force-seconds total impulse, Hyperion I launched from the Mojave Desert to an altitude of about 2000 feet in May 2023. A 36 inch parachute was deployed a few seconds after apogee, followed by a successful recovery, completing the requirements for my Level 1 Certification.

Hyperion I clearing the launch rail during the powered ascent portion of its flight.

Picture taken from the onboard flight camera during the powered ascent phase.

Hyperion I on the launch pad, just after attaching the ignition wires, and a few minutes before launch.

Picture taken from the onboard flight camera during apogee.

A video of the launch, from liftoff to parachute deployment, taken by the onboard flight camera.

CNC Practice Part

This section is currently in progress – please check back in later!

School Projects

Aluminum Medallion Casting

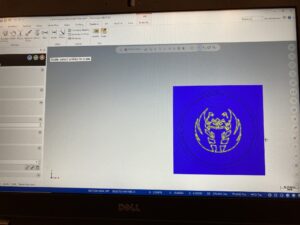

I designed and made an aluminum medallion casting, from CAD/CAM to a finished product.

Two-Person Bike Seat

This section is currently in progress – please check back in later!